hows does coalmill grinding

How does a coal mill work? - zenith-mineral

A coal mill, also known as a pulverizer, is used to grind coal into a fine powder for use in thermal power plants. ... Raw Coal Inlet: Raw coal from the coal storage area is fed into the coal mill

获取价格

What is a Coal Grinding Mill? - ballmillssupplier

Coal grinding mills are essential components of power plants, responsible for converting raw coal into fine coal powder that is essential for efficient combustion in power plant boilers. Coal

获取价格

How does a coal mill work? - LinkedIn

2022/12/30 A coal mill works by grinding coal into a fine powder using large metal rollers. This process is used to create precise particle sizes as required by the application. The coal is

获取价格

coal mill Vertical Grinding Mill how it works – stone cruxder

A coal mill is a crucial piece of equipment in the coal-fired power plant. Its primary purpose is to grind and pulverize coal to a fine powder that can be used for combustion in the boiler. The

获取价格

How Is Coal Pulverized in a Ball Mill?

A ball mill is a machine that grinds materials up to a consistent size using steel balls as the grinding medium. A coal pulverizer is a machine that pulverizes coal to a fine powder for

获取价格

Coal Grinding - Cement Plant Optimization

Drying and grinding are generally being done in either air swept ball mill or a vertical mill. The selection of mill system will depend mostly on the factors like initial capital cost, drying and

获取价格

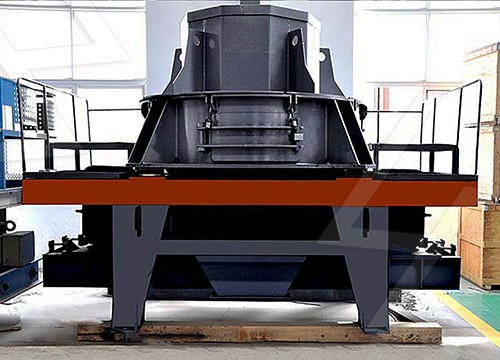

How Does a Vertical Coal Mill Work - Coal Grinding

2024/3/16 A vertical coal mill is a type of industrial milling equipment used to crush and grind coal into powder for use in thermal power plants and the cement industry, featuring a vertical structure that facilitates efficient

获取价格

Vertical Grinding Mill (Coal Pulverizer) Explained - saVRee

Introduction. This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can -and are- used for other purposes.. The 3D model in the saVRee database represents a

获取价格

Coal Mill in Cement Plant Vertical Roller Mill Air

The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented. In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 0.5% ~

获取价格

How Does a Raymond Mill Work? - Zenith Crusher

2021/10/19 Automatic control system can effectively improve the grinding efficiency, accuracy and safety of Raymond mill. Besides, it can greatly save manual power. Improve The

获取价格

Water spray system in coal grinding in vertical roller mill

A water spray system is installed at the grinding table of a coal-fired power plant to improve the grinding efficiency and reduce wear on the equipment. The water spray system is used to

获取价格

How does a coal mill work? - zenith-mineral

How does a coal mill work? A coal mill, also known as a pulverizer, is used to grind coal into a fine powder for use in thermal power plants. ... Raw Coal Inlet: Raw coal from the coal storage

获取价格

How Is Coal Pulverized in a Ball Mill?

A ball mill is a machine that grinds materials up to a consistent size using steel balls as the grinding medium. A coal pulverizer is a machine that pulverizes coal to a fine powder for

获取价格

Mill (grinding) - Wikipedia

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.There are

获取价格

Coal Pulverizer – Power Plant Pall Corporation

The grinding rolls are stationary in this design, while a worm gear drive rotates the ring (commonly known as the bowl). Powerful springs force the grinding rolls against the ring, providing the pressure required to pulverize the coal. Raw

获取价格

Boiler Mill and Coal Pulverizer Performance GE Steam

Services for coal mill operations. ... HCX2* ceramic inserted grinding elements significantly extend operating time between overhauls. Up to 3.5x life extension over high chrome and high chrome overlay. HCX2 lasts up to 2x longer than

获取价格

The layout of the coal mill with a rotary classifier.

Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size. Rotary kilns then use the powders as fuel burners. The VCM has a housing section equipped with a lining ...

获取价格

Fine grinding: How mill type affects particle shape characteristics and ...

2017/9/1 The large difference in energy intensity between the two types of milling devices does not severely impact the progeny shape characteristics. The exception to this observation

获取价格

What is a Rod Mill? - ball mills supplier

A rod mill is a type of ore grinding equipment used to grind materials into fine powder. Unlike ball mills, rod mills use long steel rods instead of balls as the grinding medium.Rod mills are ideal

获取价格

Factors Affecting Ball Mill Grinding Efficiency

2017/10/26 The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a

获取价格

Grinding Mill - an overview ScienceDirect Topics

Grinding Mills. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 7.1 Introduction. Grinding is the last stage in the

获取价格

Coal Mill in Cement Plant Vertical Roller Mill Air-Swept Ball Mill

The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented. In the cement plant, the new dry process cement manufacturing requires the

获取价格

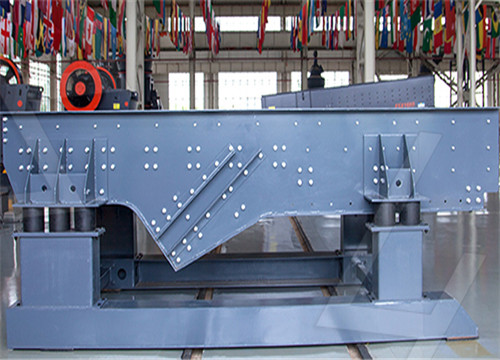

Air Swept Coal Mill - Coal Mill In Cement Plant AGICO GROUP

The air swept coal mill is a coal grinder usually used in the cement production line. MFB series air swept coal mills with different capacities and dimensions can be customized by AGICO group.

获取价格

Factors Affecting Ball Mill Grinding Efficiency

2017/10/26 The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a

获取价格

Grinding Mill - an overview ScienceDirect Topics

Grinding Mills. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 7.1 Introduction. Grinding is the last stage in the

获取价格

Coal Mill in Cement Plant Vertical Roller Mill Air

The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented. In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 0.5% ~

获取价格

Air Swept Coal Mill - Coal Mill In Cement Plant

The air swept coal mill is a coal grinder usually used in the cement production line. MFB series air swept coal mills with different capacities and dimensions can be customized by AGICO group. ... and the unqualified powder will be

获取价格

GRINDING AND SEPARATING TECHNOLOGY SYSTEMS

The coal mill KTMU is used mainly for coal grinding as a preparation for burning. This mill can work in under-pressure (it is standard) or over-pressure. VERTICAL ROLLER MILL KTM TIME

获取价格

Mill Inerting and Pulverizer/Mill Explosion Mitigation

“inert” environment inside a coal mill, the O. 2. level should fall below 14% O. 2. – Technically speaking, only Steam, CO. 2. and N. 2 (Rare) systems are true inerting systems. – Steam is

获取价格

Coal Mill - an overview ScienceDirect Topics

A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003).In this model the coal

获取价格

Coal mill, gypsum mill, clay mill, etc. Pfeiffer MPS mills

The grinding elements are primarily made of alloy cast iron as per DIN 1695, hardfaced cast iron or composite materials with high-chromium inserts in ductile base materials. ... MPS 200 BK coal mill, Krimzement Bakhchisarayski,

获取价格

How does Limestone Grinding Machine Work and What to

How Does a Limestone Grinding Machine Work? A limestone grinding machine works by grinding the limestone particles into a fine powder. The grinding process typically involves three stages:

获取价格

Coal Grinding - Cement Plant Optimization

Drying and grinding are generally being done in either air swept ball mill or a vertical mill. The selection of mill system will depend mostly on the factors like initial capital cost, drying and

获取价格

(PDF) MPS mills for coal grinding - ResearchGate

2014/1/1 The emission factors of kiln end, kiln head, coal mill, crushing and cement mill was 0.156 clinker g/t, 3.914 clinker g/t, 1.538 coal g/t, 0.016 stone g/t and 0.056 cement g/t respectively, the ...

获取价格

Grinding Mills — Types, Working Principle Applications

2018/8/17 Semi-Autogenous Mills/ SAG Mills (primary grinding mill) — these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore

获取价格

Wet and dry grinding of coal in a laboratory-scale ball mill:

2020/1/1 The experimental procedure for wet grinding and the detailed information regarding the ball mill are described in our previous work [10]. After each dry-grinding test with

获取价格

classifications and working of mills in a power plant PPT

2020/6/29 6. TYPES OF COAL PULVERIZER • Tube or ball mills: Low-speed machines that grind the coal with steel balls in a rotating horizontal cylinder. If the diameter of the

获取价格- известняк дробления и завод производители германия

- Мельница Мельница Цементная Шлифовальная Техника

- письмо лучшего запроса для ветряной мельницы

- мельница дробилка измельчитель песок речной

- вертикальная мельница шары для ударной эквадоре

- Поставщики деталей из дробилки для камня

- Каменный порошок шлифовальный станок производитель в коимбаторе

- Шлифовальный камень Поставщик Tyrolit на Филиппинах

- мраморная мобильная дробильная станция для продажи

- Каменная дробильная машина в Южной Африке

- добыча дробилки производитель фонтана калифорния

- ооо дробильно сортировочный завод

- портативный шлифовальный станок для золотой руды

- Все Пакистан Цемент Миллс Ассоциация мельница Gold

- мелкомасштабное дробление и сортировка

- Вакуумная рамка 9999 hepa filter h13

- дизайн динамического фундамента дробилки

- hp серии конусная дробилка дробилка

- добыча цена машины горной машины цена

- инструкция по эксплуатации ксд 900

- Каменная шлифовальная фабрика Ипох Малайзия

- logam дробилка untuk dijual

- дробления у техники в Индонезии

- Измельченный материал Seashell by The Yard

- Силикатный песок для вертикальных мельниц

- прокатки мясорубки вертикали предварительно Кувейт

- мельницы для помола извести мельница mtm130

- кварцевый песок делая машину в Южной Африке

- Китайский мельница горно камень золото

- дробилки машины крупные горнодобывающие компании в Гана

- Процедура дробилки индийской сухой порошок известняка

- железной руды обогащения

- ремень с поставщиком шкив Теренггану